Check Out The Name And Function Of These Pointy Rubbers Found On Tires

You might have seen these pointy rubbers found on car tires and must have wondered what it does or what it is called. Well, this article will explain to you what these pointy rubbers does on the car tires.

The name of these pointy rubbers is Vent spews or sprues. It is formed due to excess pressure escapes from as the rubber expands

Let’s take a look at its functions.

1. Gas Escape

Vent spews serve as channels for the escape of gases produced during the casting process. When molten metal fills the mold cavity, it displaces air and other gases. Without proper venting, these gases can become trapped in the casting, leading to defects like porosity.

2. Air Venting

As molten metal enters the mold, it needs to displace the air present in the cavity. Vent spews provide a pathway for this air to escape, ensuring that the metal can fill the mold completely and uniformly. Inadequate venting can result in incomplete casting and irregularities.

READ: Biden Shaken as Car Crashes into Parked Motorcade in Delaware – VIDEO (Updated)

3. Preventing Mold Erosion

The high temperature of molten metal can erode the mold material. Vent spews help direct the flow of metal away from critical areas, preventing erosion and maintaining the structural integrity of the mold.

4. Excess Material Removal

During the casting process, excess molten material may accumulate in the mold. Vent spews provide an escape route for this excess material, preventing it from becoming part of the final casting and contributing to dimensional inaccuracies or surface imperfections.

READ ALSO: Merging 9 BECE subjects into 5 or 6 for 2024 BECE: (Likely outcome)

5. Minimizing Shrinkage Porosity

Shrinkage porosity can occur as the metal cools and contracts. Vent spews aid in minimizing shrinkage porosity by allowing for the escape of gases and preventing pockets of trapped air that could lead to voids in the final casting.

6. Maintaining Pressure

Proper venting helps maintain consistent pressure within the mold cavity. This is essential for achieving uniform filling of intricate or complex shapes in the casting, ensuring that every detail is accurately reproduced.

In summary, vent spews are integral to the casting process as they address various challenges related to gas and air management, excess material removal, and mold erosion. Their strategic placement and design contribute significantly to the quality and precision of the final cast product.

Send Stories | Social Media | Disclaimer

Send Stories and Articles for publication to [email protected]

We Are Active On Social Media

WhatsApp Channel: JOIN HERE

2024 BECE and WASSCE Channel - JOIN HERE

Facebook: JOIN HERE

Telegram: JOIN HERE

Twitter: FOLLOW US HERE

Instagram: FOLLOW US HERE

Disclaimer:

The information contained in this post on Ghana Education News is for general information purposes only. While we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the post for any purpose.

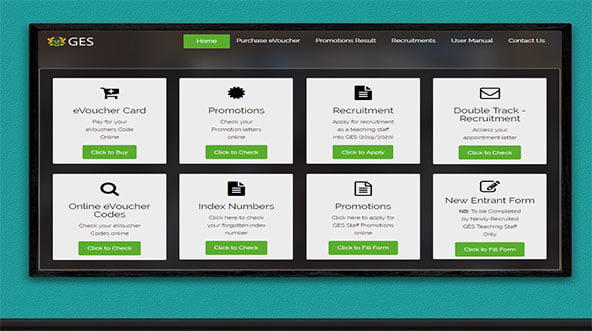

GES Opens Promotion Portal For Teaching Staff

GES Opens Promotion Portal For Teaching Staff  15 Year Old Girl Develops Anti-Sleep Device For Drivers

15 Year Old Girl Develops Anti-Sleep Device For Drivers  Emissions Levy Starts Today: Check How Much Car and Motor Owners Are Required To Pay

Emissions Levy Starts Today: Check How Much Car and Motor Owners Are Required To Pay  TVET Sector Enhances Employability through Industry Partnerships

TVET Sector Enhances Employability through Industry Partnerships  WAEC Sample BECE French Questions Paper1

WAEC Sample BECE French Questions Paper1  NaCCA/WAEC Type of Questions for May 2024 BECE Mock

NaCCA/WAEC Type of Questions for May 2024 BECE Mock  2024 Sample BECE Ga Language Questions (Ga)

2024 Sample BECE Ga Language Questions (Ga)